In the spring of 2023, a small marketing firm in Ohio replaced its entire customer service onboarding team with a single tool: ChatGPT. By the end of the quarter, customer satisfaction had jumped 12%, and costs dropped by over half. This wasn’t an isolated story; it was a snapshot of a global phenomenon. Fast forward to 2025, and OpenAI is no longer a rising star in AI innovation. It is the gravity center.

This article dives into the latest OpenAI statistics for 2025, breaking down where the company stands in terms of usage, revenue, integrations, and global impact. Whether you’re a developer, educator, business owner, or simply AI-curious, these data points will shape how you understand the AI landscape today.

Editor’s Choice

- 180 million monthly active users are now engaging with ChatGPT, marking a sharp rise from just 100 million the previous year.

- OpenAI’s projected revenue for 2025 is $3.4 billion, nearly doubling the $1.6 billion recorded in 2023.

- ChatGPT Enterprise now has over 600,000 paying business users, a figure that grew by 275% in the past 12 months.

- Over 92% of Fortune 500 companies are estimated to use OpenAI products or APIs in some form by mid-2025.

- The GPT-4o model can now handle over 1 million tokens in context, drastically improving document analysis workflows.

- In 2025, OpenAI has officially surpassed 60% market share in the US AI-as-a-service sector.

- Average daily queries to OpenAI’s API exceed 2.2 billion, cementing its role as the backbone for generative tools and bots.

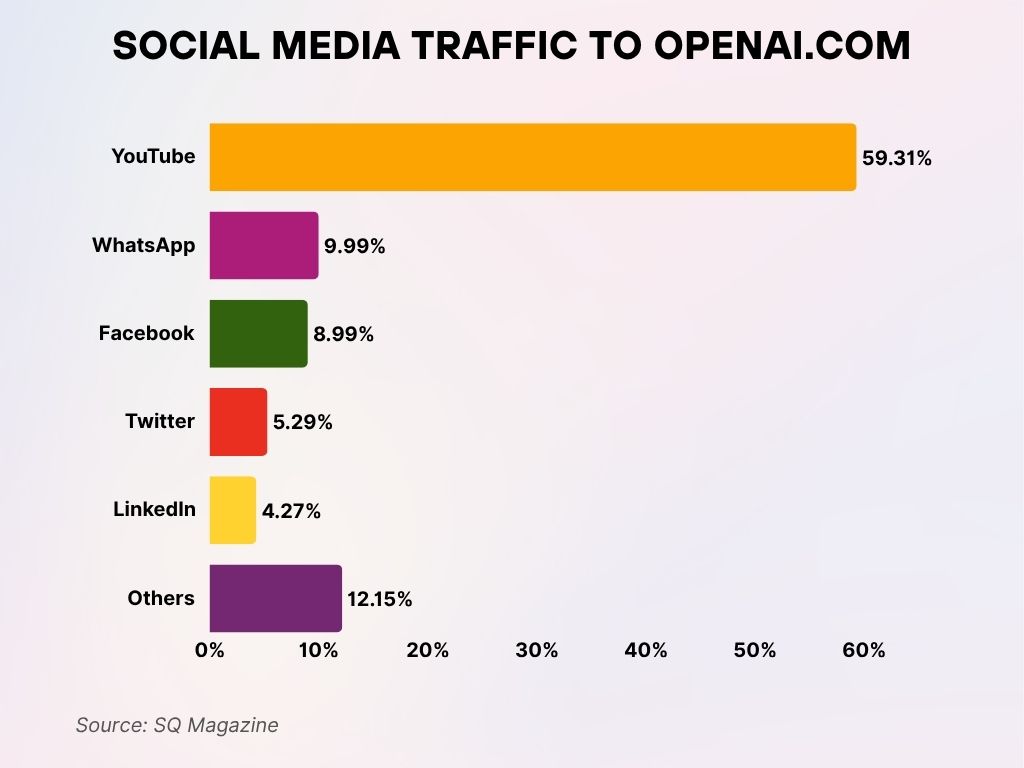

Social Media Traffic to OpenAI.com

- YouTube is the leading source of social media traffic to openai.com, driving a massive 59.31% of all traffic.

- WhatsApp contributes 9.99%, reflecting strong engagement through messaging-based sharing.

- Facebook comes in close with 8.99%, showing it still plays a role in directing visitors.

- Twitter accounts for 5.29%, indicating a moderate impact from the platform.

- LinkedIn contributes a smaller share at 4.27%, likely tied to professional and enterprise interest.

- Other social platforms collectively make up 12.15% of traffic, highlighting the influence of niche or emerging channels.

ChatGPT Adoption and Usage Metrics

- As of Q2 2025, ChatGPT has over 180 million monthly active users globally.

- The average user interacts with ChatGPT for 32 minutes per session, a 13% increase year-over-year.

- ChatGPT Plus subscriptions now total more than 7.5 million, driven largely by the release of GPT-4o with multimodal capabilities.

- Daily mobile app downloads of ChatGPT across iOS and Android exceed 290,000, indicating broadening device penetration.

- 67% of ChatGPT usage in 2025 is non-English, showing significant international growth.

- The tool is now embedded in more than 400 browser extensions and productivity apps.

- Over 2.3 billion messages are processed weekly through ChatGPT.

- 57% of Gen Z internet users in the US report using ChatGPT at least weekly.

- ChatGPT’s voice chat feature now accounts for 19% of total user engagement.

- Daily interactions from education platforms increased by 73% year-over-year.

OpenAI Revenue and Valuation Figures

- OpenAI is forecasted to hit $3.4 billion in 2025 revenue, more than double its 2023 revenue.

- Licensing deals and enterprise agreements make up 56% of total revenue.

- OpenAI’s valuation as of Q2 2025 stands at approximately $90 billion.

- The company’s net annual profit is expected to cross $1 billion for the first time.

- ChatGPT Plus accounts for approximately $1.1 billion in annual recurring revenue (ARR).

- Microsoft’s total financial backing of OpenAI now exceeds $13 billion as of 2025.

- The education sector now contributes $230 million annually to OpenAI’s revenue.

- OpenAI’s cloud spend on Microsoft Azure exceeded $1.8 billion this year.

- More than 140 countries contribute to OpenAI’s revenue streams, showing global monetization traction.

- Valuation projections suggest OpenAI could cross the $120 billion mark by the end of 2025 if private secondary market trends hold.

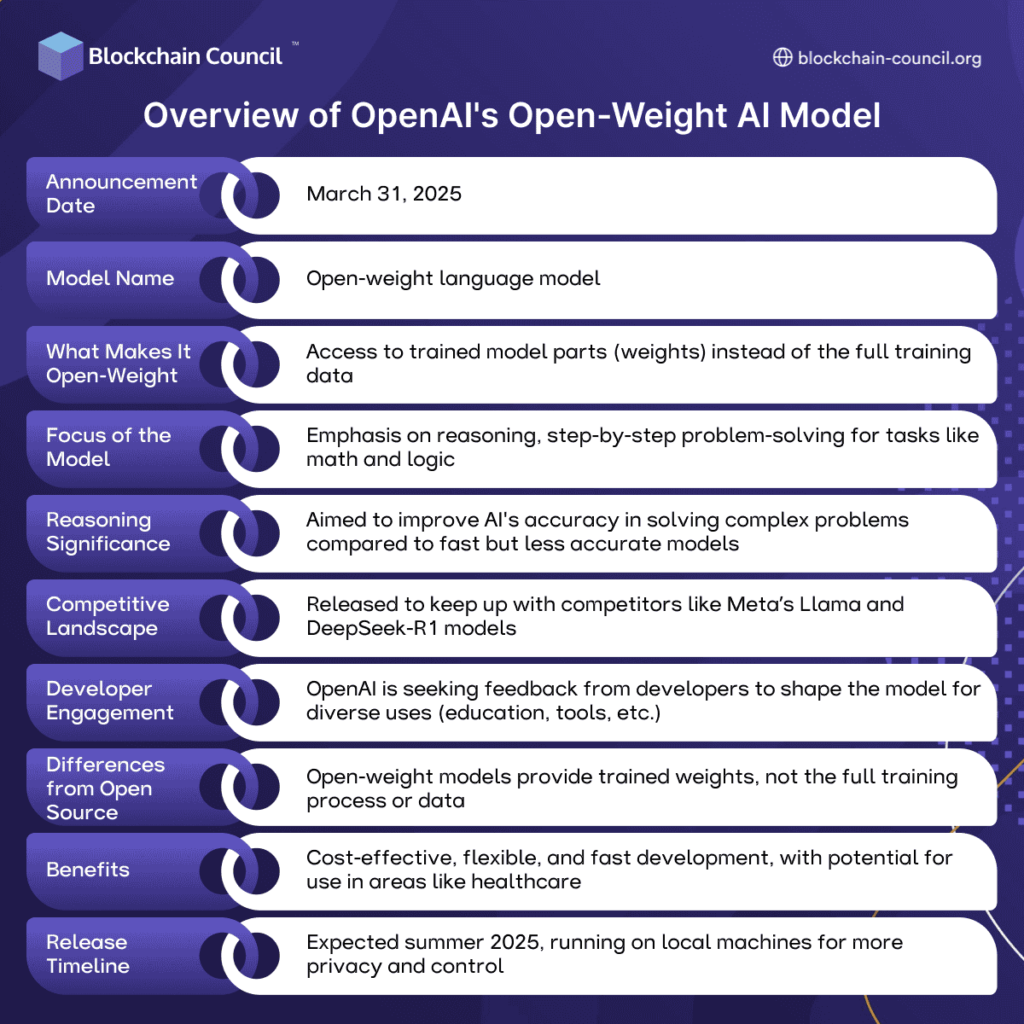

Overview of OpenAI’s Open-Weight AI Model

- Announced on: March 31, 2025

- Model Type: Open-weight language model

- Key Feature: Provides access to trained model weights, not the full training data.

- Primary Focus: Designed to enhance reasoning and step-by-step problem-solving, especially for math and logic tasks.

- Reasoning Advantage: Aims to boost AI accuracy in complex scenarios, improving over fast but less precise models.

- Competitive Strategy: Launched to compete with Meta’s Llama and DeepSeek-R1 models.

- Developer Involvement: OpenAI is actively seeking feedback from developers across domains like education and tool creation.

- Not Open Source: Shares trained weights only, not full data or training processes.

- Core Benefits: Offers a cost-effective, flexible, and rapid development option, ideal for healthcare and other sensitive fields.

- Expected Launch: Summer 2025, with a focus on local deployment for enhanced privacy and control.

API Usage and Developer Engagement

- Daily API calls surpassed 2.2 billion in 2025, up from 1.3 billion last year.

- Over 2.1 million developers are actively building on the OpenAI platform as of Q2 2025.

- The average enterprise customer integrates OpenAI’s API into 5+ internal apps or workflows.

- 40% of GitHub’s most forked repositories in the AI category now rely on OpenAI APIs.

- 70% of new OpenAI API signups in 2025 come from outside the United States.

- API usage from browser plug-ins and extensions has grown by 148% year-over-year.

- OpenAI’s developer documentation site now sees 16 million monthly visits.

- Monthly active apps using OpenAI’s function-calling feature exceed 85,000.

- A new cohort of 65,000 student developers was onboarded through OpenAI’s free tier in Q1 2025 alone.

- 28% of all OpenAI API usage comes from no-code or low-code platforms like Zapier, Bubble, and Retool.

Enterprise and Education Integration Rates

- As of Q2 2025, over 92% of Fortune 500 companies utilize OpenAI technology across departments.

- ChatGPT Enterprise usage has scaled to over 600,000 business customers globally.

- 68% of Fortune 100 firms now use OpenAI tools in their R&D workflows.

- In the education sector, more than 21,000 schools and universities across 130+ countries have integrated OpenAI solutions.

- 75% of US universities report using GPT-based tools for tutoring, writing support, or curriculum development.

- Custom GPTs tailored for academic use have grown by 310% year-over-year.

- The OpenAI API powers over 3,400 edtech apps and platforms as of mid-2025.

- 58% of educators surveyed in the US use OpenAI products weekly for lesson planning or feedback generation.

- Higher education institutions saw a 37% cost reduction in online course administration using AI-powered systems.

- 14% of K–12 classrooms in the US now utilize OpenAI-powered assistants directly in instruction.

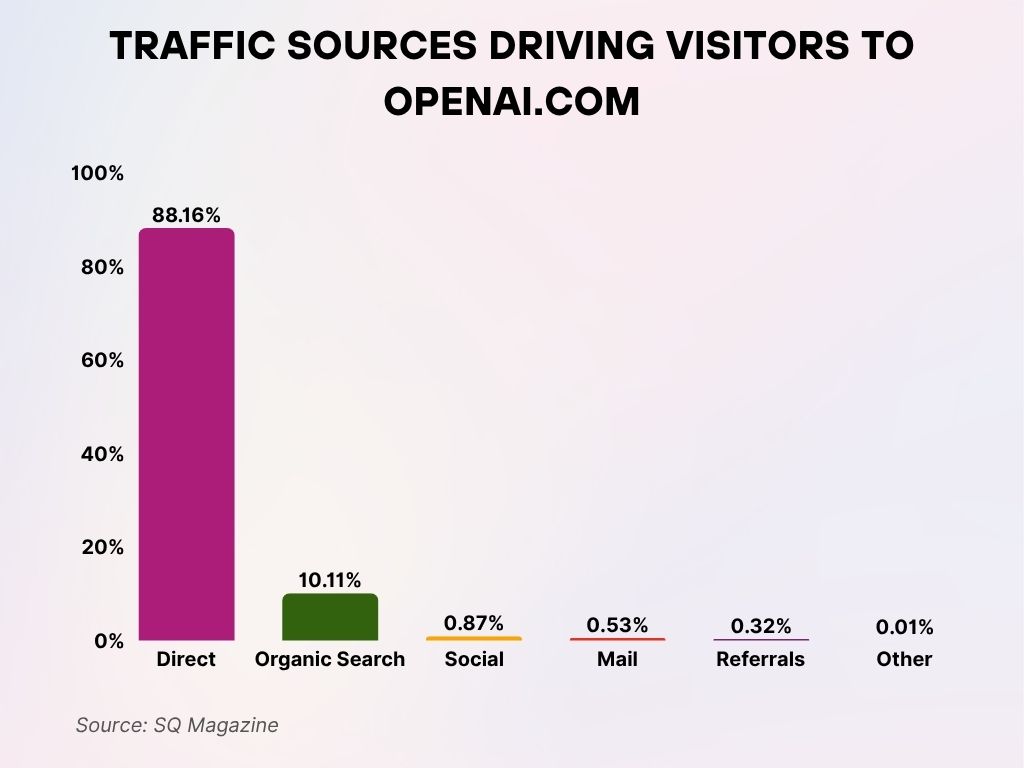

Traffic Sources Driving Visitors to OpenAI.com

- The largest share of traffic to openai.com comes from Direct visits, accounting for a dominant 88.16%.

- Organic search contributes 10.11%, indicating strong discoverability via search engines like Google.

- Social media brings in just 0.87%, showing limited reliance on social platforms for site traffic.

- Email campaigns (Mail) account for 0.53% of the traffic.

- Referral links make up a modest 0.32%, highlighting minimal traffic from external websites.

- Other sources contribute only 0.01%, indicating a very low impact from miscellaneous channels.

Model Performance Benchmarks (GPT-4, GPT-4o, etc.)

- GPT-4o can now process up to 1 million tokens in a single context window.

- On the MMLU benchmark, GPT-4o scores 89.7%, outperforming all prior models.

- Image recognition accuracy for GPT-4o increased to 94%, narrowing the gap with specialized vision models.

- Latency for API responses dropped to an average of 190ms with the GPT-4o turbo variant.

- GPT-4o supports fully multimodal interaction with text, image, audio, and video inputs.

- Audio generation models can now create natural-sounding voices in 18 languages, with prosody accuracy exceeding 96%.

- Code generation success rate with GPT-4o reaches 92% on HumanEval benchmarks.

- GPT-4o performs at or above expert-level in 17 of 20 professional licensing exam simulations.

- Multi-step reasoning in GPT-4o improved by 23% compared to GPT-4-turbo in 2024 benchmarks.

- Average time to generate and validate complex scientific calculations reduced by 41% with GPT-4o integration.

Market Share Among AI Providers

- As of 2025, OpenAI holds an estimated 61% share of the US generative AI market.

- Globally, OpenAI products are used by 72% of enterprises working with AI.

- In the consumer space, ChatGPT is the most-used AI assistant in 89 countries.

- OpenAI’s share of API-based AI infrastructure surpasses 50%, outpacing rivals like Anthropic and Cohere.

- Azure OpenAI Service adoption rose 64% year-over-year, primarily due to enterprise deployments.

- OpenAI surpassed Google DeepMind in enterprise benchmark usage for the first time in Q1 2025.

- 42% of all new SaaS platforms with AI components launched in 2025 rely on OpenAI models.

- AI-driven productivity tools built on OpenAI outnumber other LLM providers’ tools by a 3:1 ratio.

- OpenAI is now integrated into 9 of the top 10 cloud providers’ developer ecosystems.

- In real-time customer support bots, OpenAI commands 48% market share.

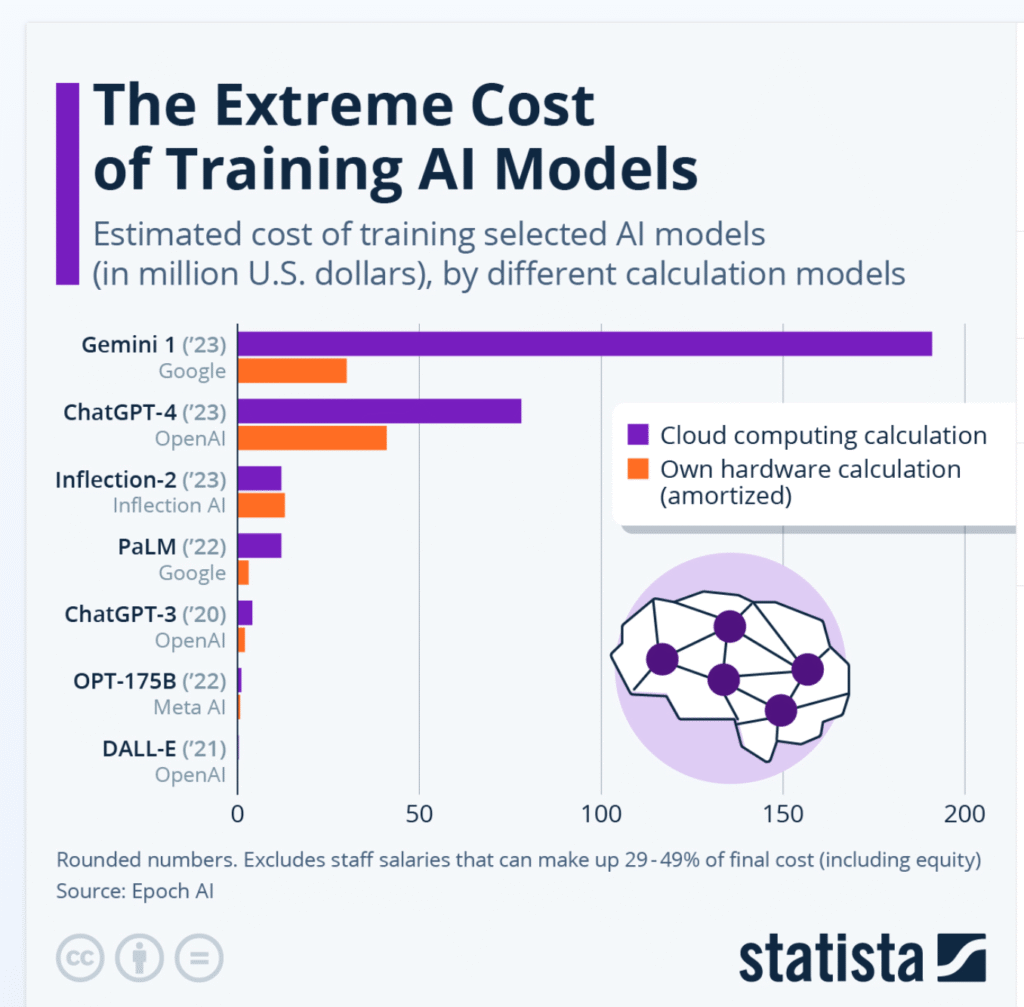

The Extreme Cost of Training AI Models

- Gemini 1 (2023) by Google tops the list with an estimated $191 million training cost using cloud computing, and around $64 million using its own hardware.

- ChatGPT-4 (2023) by OpenAI follows with $78 million using cloud resources, and about $51 million on its own infrastructure.

- Inflection-2 (2023) by Inflection AI cost around $31 million via cloud, and roughly $21 million on owned hardware.

- PaLM (2022) by Google incurred a cloud-based cost of $30 million, and about $18 million using amortized internal hardware.

- ChatGPT-3 (2020) cost OpenAI an estimated $20 million on cloud, and $13 million via internal compute.

- OPT-175B (2022) by Meta AI had a lower training cost of about $15 million cloud-based and $9 million in hardware-based terms.

- DALL·E (2021) by OpenAI was among the least costly to train, with $9 million cloud costs and $6 million via its own hardware.

Note: These figures exclude staff salaries, which could account for 29%–49% of the total cost.

Global Reach and Language Support

- OpenAI now supports 52 languages natively across ChatGPT and API services.

- Multilingual usage accounts for 67% of ChatGPT’s total queries in 2025.

- The fastest growth regions for OpenAI in 2025 are Southeast Asia, Latin America, and Sub-Saharan Africa.

- Voice and text services are now localized in 24 major dialects beyond standard language variants.

- GPT-4o supports real-time translation in 40+ languages with accuracy rates surpassing 94%.

- OpenAI’s top 5 non-English markets are India, Brazil, Japan, Germany, and Mexico.

- Usage in Africa grew by 204% year-over-year, driven by mobile-first platforms using OpenAI’s API.

- ChatGPT app usage in non-English languages increased by 58% in Q2 2025.

- 7 of the top 10 global education platforms using OpenAI are based outside North America.

- Content moderation systems now work effectively across 45 languages.

OpenAI Research Output and Publication Trends

- OpenAI published 87 peer-reviewed papers in the first half of 2025, spanning NLP, robotics, and cognitive science.

- GPT-4o underpins over 1,200 academic citations in 2025 YTD, across fields from law to physics.

- The number of research collaborations doubled to 220+ institutions globally.

- 9 OpenAI researchers were recognized in the top 100 most-cited AI scientists of 2025.

- Research focus in 2025 shifted toward multimodal learning, interpretability, and ethical alignment.

- OpenAI launched 3 new public research challenges, including a benchmark for AI-generated misinformation detection.

- Its datasets team released 4 new open datasets for reproducible research in LLM transparency.

- Technical blog readership surpassed 4.6 million monthly views, a 34% rise YoY.

- OpenAI contributed to 6 joint papers with university consortia on AI policy impact.

- The OpenAI Researcher Access Program expanded to fund 50 external PhDs for aligned AI safety research.

Top AI Tools Preferred by Marketers

- ChatGPT leads the pack, used by 55% of marketers, making it the most popular AI tool in the marketing space.

- Copy.ai comes in second, adopted by 42% of marketers for content generation and productivity.

- Jasper.ai is favored by 36%, especially for its marketing-focused writing templates.

- Peppertype.ai is used by 29% of marketers, showing strong interest in short-form and ad copy generation.

- Lensa, known for image editing and avatars, has a 28% share among marketers.

- DALL·E, another OpenAI product, is used by 25%, mostly for creating AI-generated visuals.

- MidJourney, popular for artistic image generation, is used by 24% of marketers, demonstrating the growing role of generative visuals in campaigns.

OpenAI Partnership and Licensing Metrics

- As of Q2 2025, OpenAI has over 120 strategic partnerships with global enterprises and government bodies.

- Microsoft remains OpenAI’s largest partner, powering integration via Azure in over 95% of enterprise deployments.

- OpenAI licenses its technology to more than 400 startups, including niche applications in healthcare, law, and retail.

- 35% of top-funded AI startups in 2025 list OpenAI as a foundational tech provider.

- OpenAI’s partnership with Salesforce has enabled the integration of GPT-powered CRM tools in 11,000+ companies.

- The number of embedded GPT-based tools in commercial SaaS platforms exceeds 6,800.

- Adobe, Canva, and Notion all renewed multi-year OpenAI partnerships in 2025.

- Governments in 14 countries have signed licensing agreements with OpenAI for civic services and public education.

- OpenAI’s licensing revenue in 2025 is projected to top $860 million.

- The company now supports custom licensing frameworks for regulated industries, including finance and defense.

Security, Safety, and Moderation

- In 2025, OpenAI tripled its safety budget, allocating $420 million to moderation and risk prevention.

- GPT-4o now includes real-time toxicity filtering that blocks harmful output with 98.2% accuracy.

- OpenAI’s moderation API is used in over 18,000 applications, flagging harmful content in 39 languages.

- AI alignment research spending grew by 62%, focusing on scalable oversight and self-auditing AI agents.

- GPT-4o incorporates chain-of-thought consistency checks in outputs for safety-critical queries.

- The company now employs 650+ people across its trust, safety, and alignment divisions.

- Daily human review audits have increased to 500,000+ samples across various use cases.

- OpenAI launched the System Card framework in 2025 to transparently report model risks and mitigations.

- The bug bounty program has paid over $6 million to ethical hackers and AI red-teamers.

- OpenAI is co-developing an international LLM Safety Index with the OECD and other policy bodies.

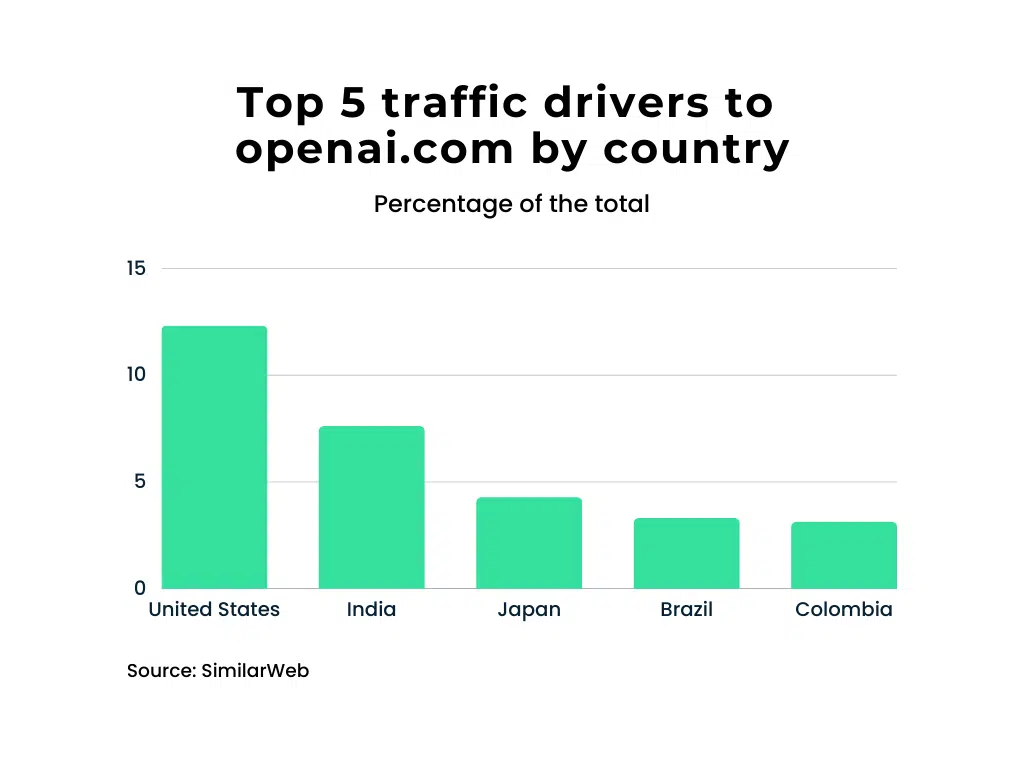

Top Countries Driving Traffic to OpenAI.com

- The United States leads with the highest share, contributing over 12% of total traffic to openai.com.

- India follows with a strong presence, accounting for approximately 7% of the site’s traffic.

- Japan ranks third, generating about 4% of the total traffic.

- Brazil comes in fourth with roughly 3%, showing growing interest from South America.

- Colombia rounds out the top five, also contributing close to 3% of total traffic.

OpenAI Employment and Talent Growth

- OpenAI’s headcount has surpassed 1,200 full-time employees in 2025, growing 40% year-over-year.

- 32% of staff are in research or technical development roles.

- OpenAI’s New York and London offices now host over 300 team members each.

- The company hired talent from Google DeepMind, Anthropic, Apple, and Meta in 2025’s competitive AI job market.

- Average engineer compensation (total package) now exceeds $710,000 annually.

- OpenAI Fellowship programs supported 78 early-career researchers in 2025.

- Employee satisfaction scores remained high at 4.7/5, based on internal surveys.

- 44% of OpenAI staff in 2025 identify as women or non-binary.

- The company opened its first dedicated AI safety research campus in Palo Alto this year.

- OpenAI’s job portal received over 400,000 applications in the first half of 2025 alone.

Recent Developments

- In May 2025, OpenAI unveiled GPT-4o, its most powerful multimodal model yet.

- ChatGPT received a major update allowing custom memory across all user tiers.

- OpenAI’s collaboration with Reddit enabled GPTs to train on public subreddit content with opt-in controls.

- The OpenAI Store now hosts over 500,000 custom GPTs.

- A new audio-to-video model was previewed internally, capable of generating dynamic avatars from voice.

- OpenAI acquired MultiScope, a startup specializing in symbolic reasoning and logical inference, in Q1.

- A redesigned ChatGPT UI was launched across all platforms with accessibility enhancements.

- Developers now access OpenAI’s real-time collaboration tools in beta via the Playground interface.

- The company introduced GPT-Assist, a coding companion with IDE plugins for VSCode, JetBrains, and more.

- OpenAI formalized an advisory board for ethics and governance, including experts from MIT, Oxford, and Stanford.

Conclusion

In just a few years, OpenAI has evolved from a cutting-edge research lab into a global force reshaping how humans interact with machines. The 2025 statistics reveal not only staggering user growth and revenue but also deeper integration into enterprise systems, education, and global infrastructure. OpenAI’s influence now stretches across 140+ countries, reaching students, scientists, and startups alike.

Whether you see OpenAI as a developer tool, an enterprise backbone, or a digital learning partner, one thing is clear: artificial intelligence is no longer on the horizon; it’s here, it’s integrated, and it’s scaling fast.

Sources

- https://www.statista.com/topics/10406/openai/

- https://www.cnbc.com/2025/06/09/openai-hits-10-billion-in-annualized-revenue-fueled-by-chatgpt-growth.html

- https://www.reuters.com/technology/artificial-intelligence/openais-weekly-active-users-surpass-400-million-2025-02-20/

- https://www.pymnts.com/artificial-intelligence-2/2025/report-openai-expects-new-products-to-drive-revenue-to-125-billion-in-2029

- https://www.statista.com/statistics/1602869/timeline-of-ai-agent-integration-in-business/

- https://www.zdnet.com/article/openais-most-impressive-move-has-nothing-to-do-with-ai/

- https://www.businessinsider.com/sam-altman-openai-crowdsourcing-fixes-chatbot-elon-musk-grok-intelligence-2024-12